Description of ER5356 Aluminium Alloy Welding Wire

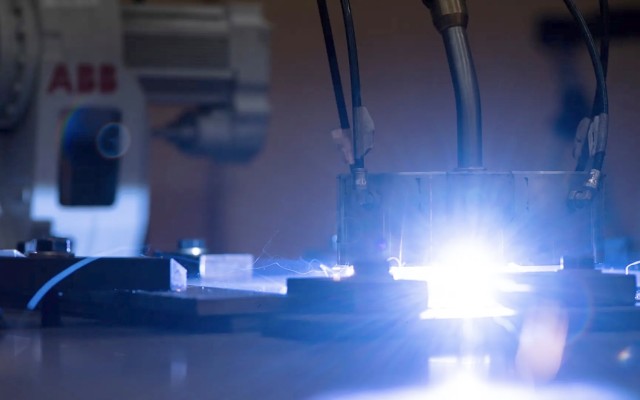

ER5356 is a type of aluminium alloy welding wire that contains 5% magnesium. It is designed specifically for welding aluminium and aluminium alloys, making it an excellent choice for various welding applications. This welding wire is lightweight and offers both strength and durability, making it ideal for a range of welding projects.

Advantages of ER5356 Aluminium Alloy Welding Wire

ER5356 Aluminium Alloy Welding Wire offers several benefits over other types of welding wire. These include excellent weldability, good corrosion resistance, and high strength. Additionally, this welding wire is easy to feed, and its consistent performance makes it suitable for experienced welders as well as beginners. Other benefits of ER5356 Aluminium Alloy Welding Wire include:

1. Corrosion Resistance

ER5356 Aluminium Alloy Welding Wire has high resistance to corrosion, making it an ideal choice for welding aluminium structures that will be exposed to harsh environmental conditions. This welding wire is particularly useful for welding marine structures, as it can resist corrosion from saltwater.

2. High Strength

ER5356 Aluminium Alloy Welding Wire offers a high level of strength and durability, making it an excellent choice for welding aluminium structures that require robust and long-lasting welds. The use of this welding wire can improve the strength of the structure, making it more resistant to wear and tear.

3. Versatility

ER5356 Aluminium Alloy Welding Wire is incredibly versatile and is compatible with a wide range of welding processes, including TIG, MIG, and stick welding. This versatility makes it an excellent choice for different welding applications, from automotive to aerospace industries.

Applications of ER5356 Aluminium Alloy Welding Wire

ER5356 Aluminium Alloy Welding Wire is commonly used across different industries, including automotive, aerospace, marine, and construction. This welding wire is suitable for welding a range of aluminium alloys and is particularly useful for welding structures that require high strength and good corrosion resistance.

Some specific applications that ER5356 Aluminium Alloy Welding Wire is commonly used for include:

1. Welding of Aluminium Structures

ER5356 Aluminium Alloy Welding Wire is an excellent choice for welding aluminium structures such as boats, trailers, and aircraft. The welding wire delivers high strength and excellent corrosion resistance, making it suitable for applications that require robust welds.

2. Automotive Industry

ER5356 Aluminium Alloy Welding Wire is also used in the automotive industry to weld aluminium car parts that require high strength and durability. This welding wire is an excellent choice for welding aluminium car radiators, engine parts, and exhaust systems.

Conclusion

ER5356 Aluminium Alloy Welding Wire is an excellent choice for welding aluminium and aluminium alloys. Its high strength, good corrosion resistance, and excellent weldability make it a versatile and reliable welding wire. Since aluminium welding requires specific skills and knowledge, it is important to work with experienced welders who have the right knowledge and expertise to deliver high-quality welding results. With the right techniques and equipment, ER5356 Aluminium Alloy Welding Wire delivers strong, durable and long-lasting welds for various applications.