Submerged Arc Welding Flux and Wire: Meeting Industry-Specific Welding Requirements

Welding is an integral process in the manufacturing and construction industries, and it is essential to ensure quality and precision in welding. There are various types of welding processes available, but submerged arc welding (SAW) is one of the most preferred methods for joining metals due to its efficiency, ease of use, and high weld quality. SAW also produces high deposition rates, resulting in a faster and more productive welding process.

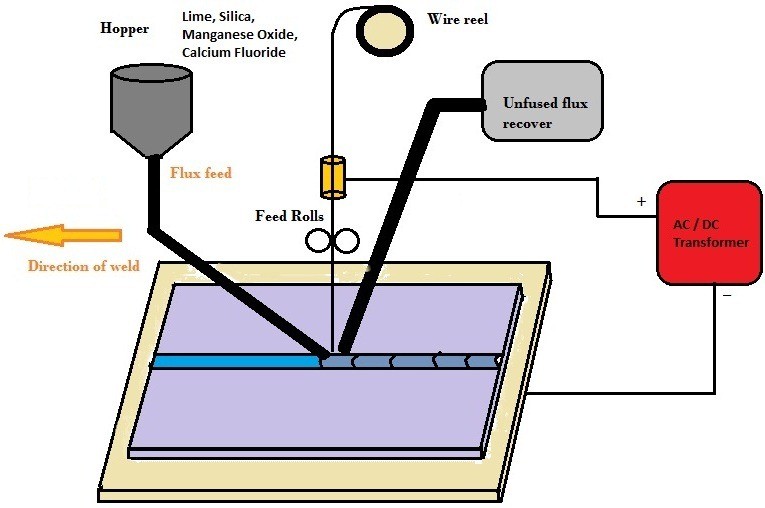

Submerged arc welding involves the formation of a weld with an electric arc that is shielded by a blanket of granular flux. The flux protects the weld from atmospheric contamination and forms a slag layer that covers the weld bead, preventing oxidation and cooling down the weld. The resulting weld is clean, smooth, and strong.

When it comes to submerged arc welding, the choice of wire and flux is critical to achieving excellent welding performance. The type of wire and flux used should be specific to the industry and application, ensuring that the welding requirements are met.

Lincoln Electric offers a wide range of submerged arc welding flux and wire designed to be paired together to meet any industry-specific welding requirement. Their products are known for their consistent quality and superior performance.

Stainless Steel Submerged-Arc Welding Wire and Flux

One of the most common types of metals used in the manufacturing and construction industries is stainless steel. It is a high-performance alloy known for its corrosion-resistant properties, making it suitable for use in harsh environments. However, welding stainless steel requires a specialized welding process, as it is prone to cracking and distortion.

Lincoln Electric has a range of submerged arc welding wire and flux specifically designed for welding stainless steel. Their products allow for the welding of high-quality stainless steel components that meet stringent industry standards.

Industry-Specific Welding Requirements

Different industries require different welding processes, and it is essential to use the appropriate welding wire and flux that meets the industry-specific requirements. For example, welding in the shipbuilding industry requires high-quality welds that can withstand the harsh marine environment, while welding in the oil and gas industry requires welds that can withstand high temperatures and pressures.

Lincoln Electric provides an extensive range of submerged arc welding wire and flux that meets the welding requirements of various industries. Their products cater to industries such as automotive, construction, mining, oil and gas, and shipbuilding, to name a few.

Excellent Welding Performance

The quality of the welding wire and flux used significantly impacts the welding performance, and it is essential to use products that consistently perform well. Lincoln Electric is known for its high-quality submerged arc welding wire and flux, delivering consistent welding performance.

Their products produce smooth and uniform welds with excellent penetration and deposition rates. Moreover, their products reduce the risk of weld defects and improve the overall weld quality, ensuring that the welding process is productive and cost-effective.

Conclusion

Choosing the right submerged arc welding wire and flux is critical to achieving high-quality welds that meet industry-specific welding requirements. Lincoln Electric offers a wide range of submerged arc welding wire and flux designed to perform optimally in various industries, including stainless steel welding.

Their products provide consistent and superior welding performance, resulting in high-quality welds that meet stringent industry standards. Welders and welding professionals can rely on Lincoln Electric's submerged arc welding wire and flux for their welding needs.